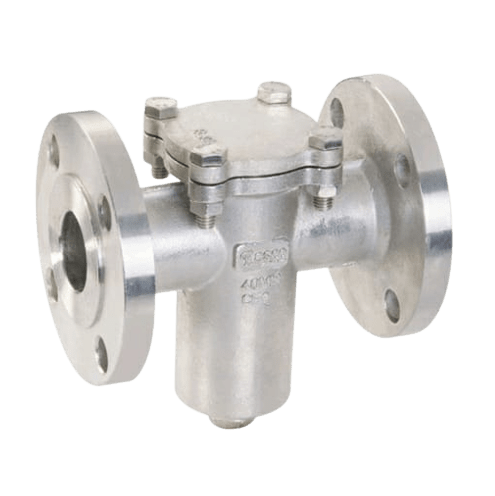

Check Valves

Industrial Check Valves Manufacturer

Swing Type Check Valves Manufacturer

Focet Valves Pvt. Ltd. is the Best Industrial Check Valves Manufacturer, Industrial Check Valves Exporter in Gujarat, and Industrial Check Valves Wholesaler in Ahmedabad. We give you Best Industrial Check Valves Prices in Ahmedabad.

|

Technical Specification

|

|

|---|---|

|

BODY & BONNET

|

ASTM A216 GR WCB / ASTM A351 GR CF8(304)/CF8M(316)

|

|

TRIMS

|

13 CR./ 18Cr 8 Ni

|

|

MFG STD

|

BS 1868

|

|

INSP & TEST STD

|

BS 6755

|

|

END

|

FLANGED TO ASME B16.5 RF 150#/300#/600#

|

|

OPEARATION

|

SELF OPERATED

|

|

HYD TEST PRESSURE

|

FOR 150#

|

|

BODY

|

425 PSIG (30KG/CM2)

|

|

SEAT

|

300 PSIG (21KG/CM2)

|

|

SIZE RANGE

|

25 MM TO 600 MM

|

Dual Plate Check Valves Manufacturer

|

Technical Specification

|

|

|---|---|

|

BODY & BONNET

|

ASTM A216 GR WCB / ASTM A351 GR CF8(304)/CF8M(316)

|

|

DISC

|

AISI SS 304/ SS316

|

|

HING PIN

|

AISI SS 304/ SS316

|

|

STOP PIN

|

AISI SS 304/ SS316

|

|

SEAT

|

EPDM

|

|

MGF STD

|

GENERALLY CONFIRMING TO API 6D/API 594

|

|

INSP & TEST STD

|

GENERALLY CONFIRMING TO API 6D/API 594

|

|

END

|

WEFAR TYPE SUIT TO ANSI B16.5 150# AND FLANGED END

|

|

HYD TEST PRESSURE

|

BODY : 425 PSIG (30KG/CM2)

|

|

|

SEAT : 300 PSIG (21KG/CM2)

|

|

SIZE RANGE

|

50 MM TO 600 MM

|

WEFAR TYPE CHECK VALVE Manufacturer

|

Technical Specification

|

|

|---|---|

|

BODY

|

CAST IRON/MS(EN8)/SS 304 / SS 316

|

|

DISC

|

MS(EN8)/ SS304 / SS 316

|

|

PIN

|

MS / SS304 / SS 316

|

|

“O” RING

|

NBR, EPDM, VITON, PTFE

|

|

MGF STD

|

GENERALLY CONFIRMING TO API 6D

|

|

TEST STD

|

GENERALLY CONFIRMING TO API 6D

|

|

ENDS

|

WEFAR TYPE

|

|

HYD TEST PRESSURE

|

BODY : 225 PSIG (16KG/CM2)

|

|

|

SEAT : 165 PSIG (11.5KG/CM2)

|

|

SIZE RANGE

|

25 MM TO 1000 MM

|

Disc Check Valves Non Slam Manufacturer

|

Technical Specification

|

|

|---|---|

|

BODY

|

ASTM A351 GR. CF8(304) / CF8M(316)

|

|

DISC

|

SS 304 / SS 316

|

|

SPRING

|

STAINLESS STEEL

|

|

SPRING RETAINER

|

AISI SS 304 / SS 316

|

|

SEAT

|

METAL TO METAL, PTFE

|

|

INSP & TEST STD

|

API 598

|

|

HYD TEST PRESSURE

|

BODY : 854 PSIG (60 KG/CM2)

|

|

|

SEAT : 569 PSIG (40 KG/CM2)

|

|

SIZE RANGE

|

15 MM TO 250 MM

|

|

Sailent Features

|

|---|

|

Rigid and Sturdy design with minimum loss of ahead across the valve.

|

|

Perfect Interchangeability of components.

|

|

Assured Parallelism of components.

|

|

Assured equal taper on both sides of the wedges.

|

|

Perfect Machining and pressing of body and wedge face ring.

|

|

Long service life and leak Tightness even after thousand of open/closed cycles.

|

|

Excellent finish on spindle threads resulting in low friction and smoother operation of valves.

|

Get a free Quote

Download Brochure

Want to find out more about our high-quality products? You can download our product catalogue right here.