Steam Traps

Industrial Steam Traps Manufacturer

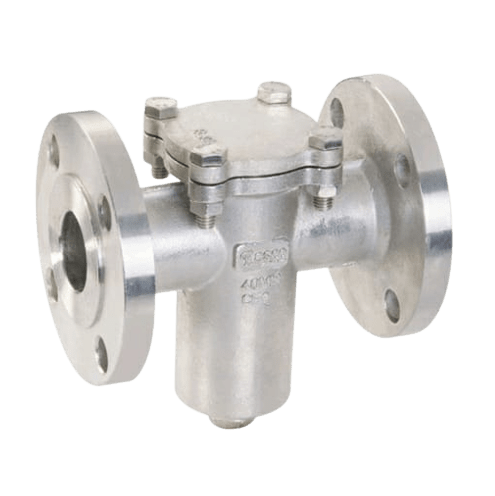

TD-3 Thermodynamic Steam Traps with Inbuilt Strainers Manufacturer

Focet Valves Pvt. Ltd. is the Best Industrial Steam Traps Manufacturer, Industrial Steam Traps Exporter in Gujarat, and Industrial Steam Traps Wholesaler in Ahmedabad. We give you Best Industrial Steam Traps Prices in Ahmedabad.

|

Technical Specification

|

|

|---|---|

|

BODY

|

ASTM A351 GR CA-15(SS410)

|

|

TRIMS

|

13 CR./ 18Cr 8 Ni

|

|

MAX. INLET PRESSURE

|

32 KG/CM2 AT 425 C

|

|

MINIMUM PRESSURE

|

0.25 KG/CM2

|

|

MAX. BACK PRESSURE

|

SHOULD NOT EXCEED 80% OF THE INLET PRESSURE

|

|

ENDS

|

SCREWED TO BSP / SOCKET WELD

|

|

SIZE RANGE

|

15 MM TO 50 MM

|

Horizontal Inverted Bucket Type Steam Traps Manufacturer

|

Technical Specification

|

|

|---|---|

|

BODY

|

IS 210 GR FG200 CAST IRON

|

|

COVER

|

IS 210 GR FG200 CAST IRON

|

|

TRIMS

|

GUM METAL AND SS 304

|

|

MAX. INLET PRESSURE

|

10.54KG/CM2 AT 220 C

|

|

MFG STD

|

IS 12268

|

|

INSP & TEST STD

|

IS 12268

|

|

ENDS

|

SCREWED END TO BSP

|

|

HYD TEST PRESSURE

|

BODY : 300 PSIG (21 KG/CM 2)

|

|

SIZE RANGE

|

15 MM TO 50 MM

|

Horizontal Ball Float Type Steam Traps Manufacturer

|

Technical Specification

|

|

|---|---|

|

BODY

|

IS 210 GR FG200 CAST IRON / ASTM A 216 GR WCB

|

|

COVER

|

IS 210 GR FG200 CAST IRON / ASTM A 216 GR WCB

|

|

TRIMS

|

GUM METAL AND SS 304

|

|

MAX. INLET PRESSURE

|

10.54KG/CM2 AT 220 C

|

|

MFG STD

|

IS 12268

|

|

INSP & TEST STD

|

IS 12268

|

|

END

|

SCREWED END TO BSP

|

|

HYD TEST PRESSURE

|

BODY : 300 PSIG (21 KG/CM 2)

|

|

SIZE RANGE

|

15 MM TO 50 MM

|

Vertical Inverted Bucket Type Steam Traps Manufacturer

|

Technical Specification

|

|

|---|---|

|

BODY

|

IS 210 GR FG200 CAST IRON

|

|

COVER

|

IS 210 GR FG200 CAST IRON

|

|

TRIMS

|

GUM METAL AND SS 304

|

|

MAX. INLET PRESSURE

|

10.54KG/CM2 AT 220 C

|

|

MFG STD

|

IS 12268

|

|

INSP & TEST STD

|

IS 12268

|

|

END

|

SCREWED END TO BSP

|

|

HYD TEST PRESSURE

|

BODY : 300 PSIG (21 KG/CM 2)

|

|

SIZE RANGE

|

15 MM TO 50 MM

|

|

Sailent Features

|

|---|

|

Rigid and Sturdy design with minimum loss of ahead across the valve.

|

|

Perfect Interchangeability of components.

|

|

Assured Parallelism of components.

|

|

Assured equal taper on both sides of the wedges.

|

|

Perfect Machining and pressing of body and wedge face ring.

|

|

Long service life and leak Tightness even after thousand of open/closed cycles.

|

|

Excellent finish on spindle threads resulting in low friction and smoother operation of valves.

|

Get a free Quote

Download Brochure

Want to find out more about our high-quality products? You can download our product catalogue right here.