Strainer Ball Valves Manufacturer

Table of Contents

Introduction

We at “Focet Valves Pvt Ltd,” a company that has been around for a while, manufacture and supply the highest quality selection of gate valves, pulp valves, globe valves, sight glasses, pinch valves, check valves, steam traps, non-return valves, etc. These goods are made from premium raw materials that are purchased from reputable industry suppliers. The goods are offered in a variety of specifications to meet the individual demands of customers, and they are carefully constructed in accordance with established industry standards. as well as We are the Best Industrial Valves Exporter in Gujarat Ahmedabad. We are the best strainer ball valves supplier.

In the industrial world, valves are essential for maintaining efficient operations in a variety of sectors. Among the many different kinds of valves, strainer ball valves have become well-known for their performance, dependability, and versatility. These valves ensure a cleaner and more effective system by filtering trash in addition to controlling fluid flow. Focet Valves, a reputable manufacturer, is a market leader if you’re looking for premium strainer ball valves.

Understanding Strainer Ball Valves

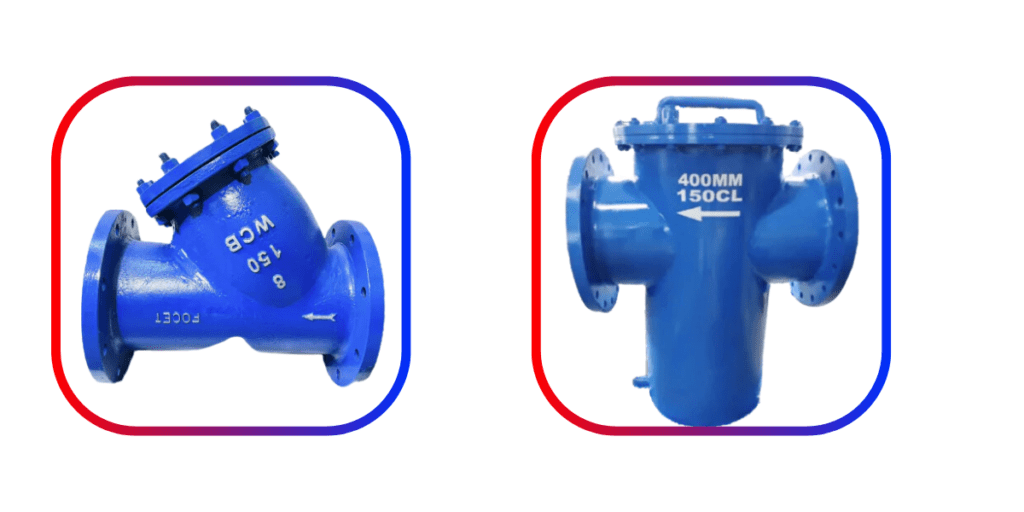

Specialised valves known as strainer ball valves incorporate a strainer device inside the valve body. This special combination has two functions: it filters away particles or waste while also regulating the flow of liquids or gases. Because of this, they are extremely useful in applications that call for both filtration and flow control.

Key Features of Strainer Ball Valves:

- A two-in-one design combines the capabilities of a strainer and a ball valve.

- Durability: Constructed to resist high pressure and corrosive conditions using sturdy materials like PVC, brass, or stainless steel.

- Easy Maintenance: Cleaning or replacing the strainer is simple and won’t interfere with the valve’s functionality.

- Versatile Uses: Found in a variety of industries, including water treatment, chemicals, and oil and gas.

- Cost-effective: Saves money and space by eliminating the need for additional straining equipment.

Applications of Strainer Ball Valves

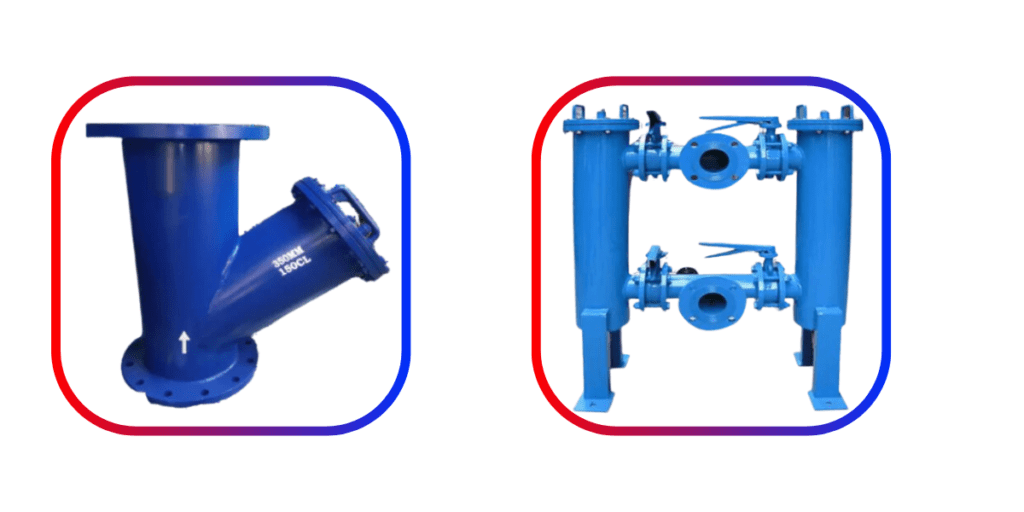

Because of its dual usefulness and dependability, strainer ball valves are used in many different sectors. Here are a few typical uses:

- Plants that treat water

Strainer ball valves aid in the removal of sediments and debris from water during water treatment procedures, guaranteeing the output’s purity and safeguarding downstream machinery. - The Gas and Oil Sector

In refineries and pipelines, these valves are essential because they filter contaminants, guaranteeing that gas and oil flow freely and unhindered. - Processing of Chemicals

In chemical industries, where it is typical to handle dangerous and corrosive fluids, strainer ball valves provide efficiency and safety. - Air Conditioning and Heating Systems

Strainer ball valves are essential to heating, ventilation, and air conditioning systems because they keep fluid flow clean and enhance system performance. - The Food and Drink Sector

In the food and beverage processing industries, strainer ball valves are essential for maintaining hygienic conditions and eliminating impurities.

Advantages of Using Strainer Ball Valves

- Enhanced System Efficiency: These valves guarantee smooth operations and avoid blockage by sifting out trash.

- Lower Maintenance Costs: By shielding equipment from impurity-induced damage, the system’s lifespan is increased.

- Compact Design: Consolidates two functions into a single component, saving space.

- Increased Safety: Removes the possibility of contamination and obstructions in vital procedures.

- Long-Term Reliability: Constructed from premium materials, these valves provide outstanding performance throughout time.

Why Choose Focet Valves?

- Unwavering Excellence

Quality is of utmost importance to Focet Valves. Every valve is put through a rigorous testing process to make sure it satisfies international standards and offers consumers dependable and long-lasting products. - Creative Designs

The company’s internal research and development team is constantly working to create cutting-edge valves that meet the needs of contemporary industry. With the newest technologies, Focet Valves’ strainer ball valves offer optimal efficiency. - Personalisation

Since every sector has different needs, Focet Valves provides solutions that are specifically designed to meet those needs. To fit their unique applications, customers can select from a variety of materials, sizes, and specifications. - Reasonably priced

Even though Focet Valves produces high-end goods, they guarantee affordability, so a variety of businesses can use their valves. - Outstanding Customer Service

Focet Valves prides itself on providing unmatched customer care, from pre-purchase consultations to post-purchase assistance. The group is always available to help clients with their requirements.

How to Select the Right Strainer Ball Valve

Selecting the ideal strainer ball valve is essential to guaranteeing peak performance. Here are some things to think about:

- Compatibility of Materials

Choose a valve that is constructed from materials that are suitable with the fluid it will be handling. For example, PVC performs well in non-corrosive situations, but stainless steel is best suited for corrosive settings. - Ratings for Temperature and Pressure

Make sure the valve can tolerate your system’s operational pressure and temperature. - Size of Strainer Mesh

Select a strainer mesh size that will allow the desired particles to be filtered without blocking flow. - Dimensions and Size

Select a valve that will work well with your current pipeline without requiring significant adjustments. - Reputation of Manufacturers

Select a trustworthy manufacturer, such as Focet Valves, at all times to guarantee dependability and quality.

Maintenance Tips for Strainer Ball Valves

Use these maintenance suggestions to extend the life and effectiveness of your strainer ball valves:

- Frequent Inspection: Look for wear and tear or leaks on a regular basis.

- Clean the Strainer: To avoid blockage, periodically remove and clean the strainer mesh.

- Lubrication: To prevent wear and friction, make sure the valve’s components are properly lubricated.

- Replace Damaged Parts: To avoid system failure, replace any worn-out or damaged parts as soon as possible.

- Observe Manufacturer Guidelines: For best performance, follow the manufacturer’s maintenance recommendations.

Conclusion

Because they provide the ideal balance of flow control and filtering, strainer ball valves are an essential part of many different industries. Focet Valves, a reputable manufacturer of strainer ball valves, is distinguished by its dedication to excellence, creativity, and client satisfaction. Focet Valves is the preferred option for industries all over the world because of its extensive product line and commitment to quality. We are the best strainer ball valves exporter.

Focet Valves offers the ideal option for any business needing dependable valves, including the water treatment and oil and gas sectors. To find out more about Focet Valves’ offerings and how they may meet your unique requirements, get in touch with them right now.